Transportverpakking: bescherm uw producten en optimaliseer uw logistiek

Uw producten beschermen en logistiek optimaliseren doet u met een transportverpakking van Nedupack Thermoforming. Wij zijn dé specialist als het gaat om het ontwikkelen en produceren van transportverpakkingen. Wij maken uw transportverpakking volledig op maat, zodat deze perfect aansluit bij uw product. Dit doen wij met behulp van een breed machinepark, onze eigen matrijzenmakerij en ontwikkelafdeling. Wij maken daarbij (afhankelijk van uw product) gebruik van een grote diversiteit aan materialen. Bij Nedupack Thermoforming vindt u alles onder één dak, van het eerste ontwerp tot uiteindelijke productie en warehousing. Samen ontwikkelen wij de verpakking waar u naar op zoek bent!

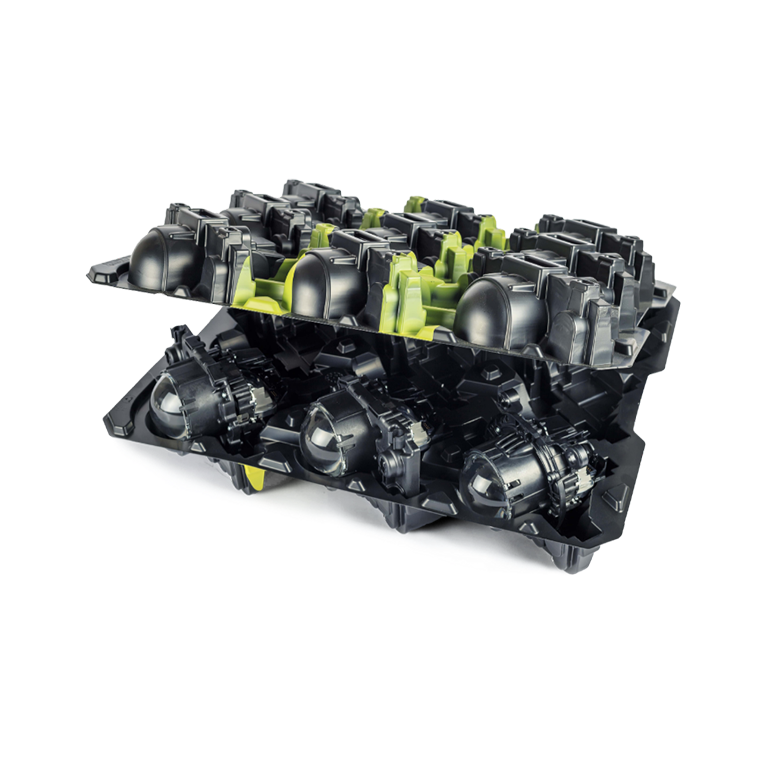

Transportverpakkingen: van transport tray tot klapblister

Binnen de industriële sector kunt u denken aan verschillende soorten transportverpakkingen. Zo ontwikkelen wij bijvoorbeeld transport trays, klapblisters, bufferkappen en beschermende verpakkingen (van onze partner ReFlex), doos- en/of kofferinterieurs, ESD verpakkingen en interne- en externe transportverpakkingen. Dit zijn slechts enkele voorbeelden van soorten verpakkingen. Aangezien wij maatwerk transportverpakkingen ontwikkelen, kijken wij samen met u naar de verpakking die het beste bij uw product past.

Voor het ontwikkelen van bijvoorbeeld een transport tray maken wij gebruik van verschillende soorten kunststof. Veelgebruikte kunststofsoorten zijn PS, A-PET, HDPE, LDPE, PC, ABS, PS-ESD, PET en dissipatief. Deze kunststofsoorten hebben met elkaar gemeen dat zij een hoge slagvastheid hebben. Daarnaast zijn ze meerdere malen te gebruiken, recyclebaar en geleiden zij elektriciteit. U bent op die manier verzekerd van een veilig en efficiënt transport van uw producten.

Uw transportverpakking en onze werkwijze

Nedupack hanteert een werkwijze waarbij wij u van A tot Z begeleiden bij het ontwikkelen van uw transportverpakking. Allereerst bespreken wij met u de wensen omtrent de verpakking. Daarbij kijken wij onder andere naar wat het beste aansluit bij uw product(en). Vervolgens gaan wij naar de tekentafel en ontwikkelen we een 3D-model. Dit model wordt doorontwikkeld naar een prototype waar vervolgens in onze matrijzenmakerij een matrijs van gemaakt word. Uiteindelijk kunnen wij snel en efficiënt uw verpakkingen produceren dankzij ons brede machinepark. Lees hier meer over de werkwijze van Nedupack Thermoforming.

Onze referenties

Wij zijn trots op onze samenwerkingen. Samen komen wij verder.

Bekijk het laatste nieuws

Verfblikken veilig transporteren

Heeft u interesse in een van onze diensten of heeft u vragen over ons maatwerk? Neem dan vrijblijvend contact met ons op.