PS plastic: characteristics and properties

Packaging made of polystyrene (PS) plastic? That’s possible at Nedupack Thermoforming. PS is a widely-used form of plastic in the packaging industry. PS is used in the form of foil. PS plastic actually consists of two different parts: High Impact Polystyrene (HIPS), a form of rubber, and Crystal, which is very hard. Because PS plastic is easily formed, it is ideally suited for the development of plastic packaging. We would like to tell you more about the PS properties and brands.

Read more about PS plasticProperties of PS plastic

Apart from being easy to form, PS has other properties that make it a suitable plastic type for packaging.

- The above combination of HIPS and Crystal can be adjusted for each application;

- PS is available in all colours, so you can match it perfectly to your product(s);

- PS plastic is widely deployable in the packaging industry;

- PS plastic is (partially) recyclable, so that it contributes towards a better environment;

- A distinguishing characteristic of PS is that it is fairly hard and has good rigidity.

However, PS plastic does not have advantages alone. Various disadvantages are also associated with this type of plastic:

- PS is not suitable for outdoor use, as it is not UV-resistant;

- PS is not suitable for greasy food types or chocolate.

Applications of PS plastic

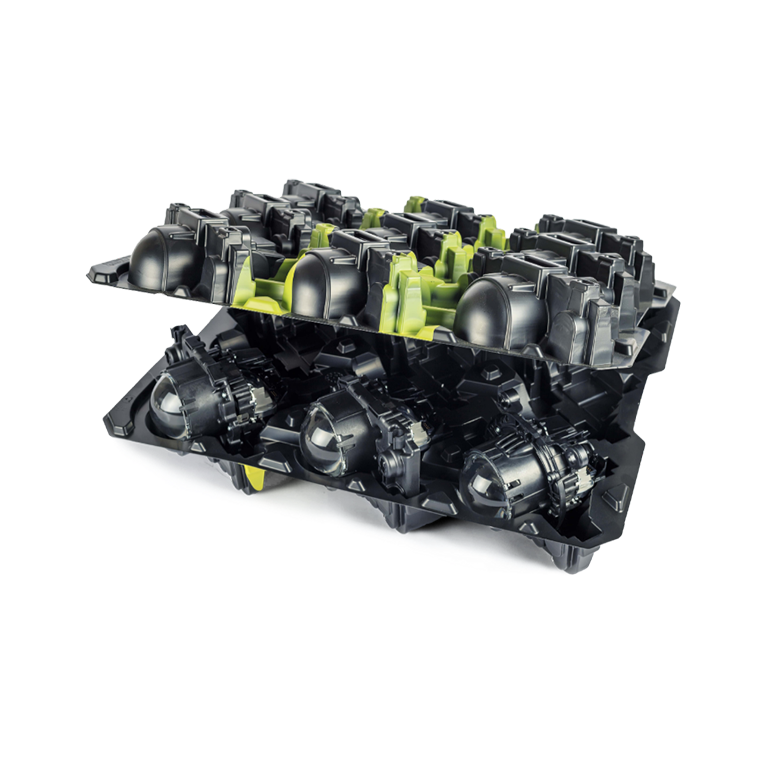

At Nedupack Thermoforming, we use PS plastic for several types of product. PS is used for the development of products including:

- Technical trays;

- Food packaging (excluding greasy food types and chocolate);

- Bi-colour products;

- Festival tokens;

- Plant labels.

Do you want customised PS packaging?

At Nedupack, it is possible to have your packaging fully custom-made. We work with you to identify your needs and requirements. We then develop a 3D model, mould and prototype, before progressing to the final production. You are closely involved in this entire process, so that we know for certain that the product meets your requirements.

Read more about our working method here.

Contact

Would you like to know more about our custom PS packaging, or do you have other questions? Please feel free to contact us on +31 (0)26 4950575 or via info@nedupack.nl.

Working method

From concept to production: our approach in 5 steps

Our references

We are proud of all our partnerships. We achieve more together.

Contact

Would you like to know more? Please feel free to contact us. Call us on +31 (0)26 4950575 or send an e-mail to info@nedupack.nl.